Immersion System

Optimal surface cleaning project, your product, your business requirements chromate in mind, is designed in the form of iron phosphate or zinc phosphate.

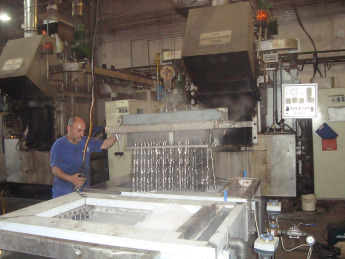

More that half of low or aluminum parts such as the size of the pieces to be painted will be painted in automated systems used in cases where limit the application of the spray system is not too large. system; chemical tanks, monorail crane and surface finishing of the pieces to be placed in the basket and consists mainly based on the chemical agent by dipping in the left to process time in the tank. Advantage compared to spray application, each point equal to penetrate the material in the immersion method ensures uniform cleaning and coating facility (the inner surface of products such as profiles and pipes). At the end of the rinsing process and speed the material to be dried.

Building material characterized by the process tank used in the system, the number and the operating temperature is determined. There are 4 mobile cranes and monorail rail system construction. Heated tanks are insulated with rock wool. Optionally heating the tanks are provided with electric resistance or hot water boiler and coil group. Chemical substances contained in the tank (oil receiver and phosphate chemicals) mixing system with compressed air is available. Drying is movable boiler manual or automatic sliding doors. In the drying vessel of the heating unit is provided with an optional heating electrical resistors, or liquid or gas burners.